Flexible PCB Guide 2025: Applications, Benefits & Design Tips for Modern Electronics

RayMing is a flexible PCB manufacturer based in China, offering comprehensive prototype-to-volume production with fast turnaround manufacturing services.

Flexible printed circuit boards (PCBs) have revolutionized modern electronics by providing unprecedented design flexibility and enabling innovative form factors that were once impossible with rigid PCBs. As we advance into 2025, flexible PCB technology continues to evolve, driving breakthroughs in wearable devices, automotive electronics, aerospace applications, and consumer electronics. This comprehensive guide explores everything you need to know about flexible PCBs, from fundamental concepts to advanced design considerations and emerging applications.

The global flexible PCB market has experienced exponential growth, reaching over $15 billion in 2024 and projected to exceed $25 billion by 2030. This growth is fueled by the increasing demand for miniaturization, lightweight solutions, and the proliferation of Internet of Things (IoT) devices. Understanding flexible PCB technology is crucial for engineers, designers, and manufacturers looking to stay competitive in today’s rapidly evolving electronics landscape.

What is a Flexible PCB?

Flexible PCBs, also known as flex circuits or flexible printed circuits, are electronic circuits fabricated on flexible substrate materials that can bend, twist, and fold without compromising electrical connectivity. Unlike traditional rigid PCBs made from fiberglass, flexible PCBs utilize polyimide, polyester, or other flexible dielectric materials as their base substrate.

The fundamental structure of a flexible PCB consists of a flexible dielectric substrate layer with conductive traces etched or deposited onto its surface. These traces carry electrical signals between components, just like rigid PCBs, but with the added benefit of mechanical flexibility. The flexible nature allows these circuits to conform to three-dimensional shapes, fit into tight spaces, and withstand repeated flexing motions.

Key Components of Flexible PCBs

Substrate Materials: The foundation of any flexible PCB is its substrate material. Polyimide is the most common choice due to its excellent thermal stability, chemical resistance, and mechanical properties. It can withstand temperatures ranging from -200°C to +400°C and maintains its flexibility across this entire range. Polyester (PET) is another popular option for cost-sensitive applications, though it has lower temperature tolerance.

Conductor Materials: Copper is the primary conductor material used in flexible PCBs, typically applied through electrodeposition or sputtering processes. The copper thickness can vary from 0.5 oz to 2 oz per square foot, depending on current carrying requirements. For specialized applications, silver or other conductive materials may be used.

Adhesives and Coverlay: Adhesive layers bond the copper conductors to the substrate and provide environmental protection. Acrylic-based adhesives are common for general-purpose applications, while high-temperature applications may require silicone or other specialized adhesive systems. Coverlay materials protect the circuit traces from environmental damage and provide electrical insulation.

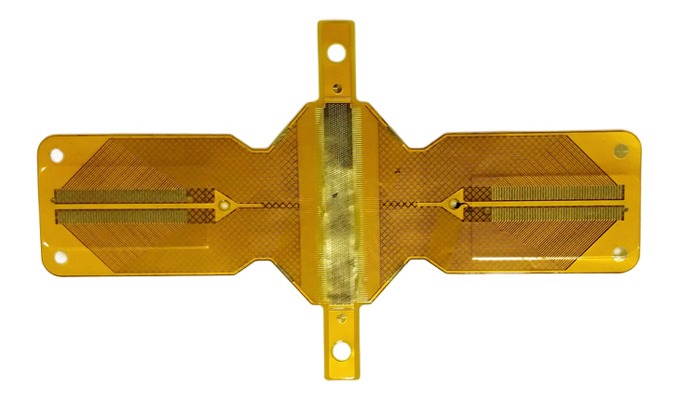

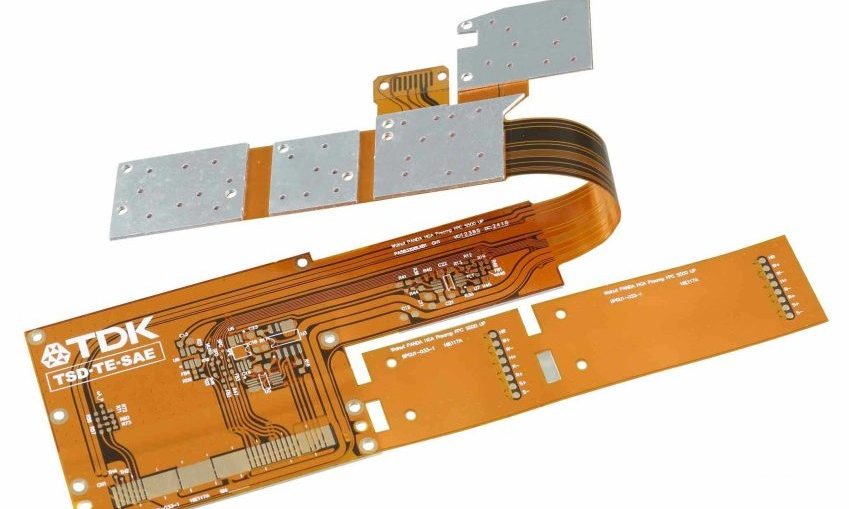

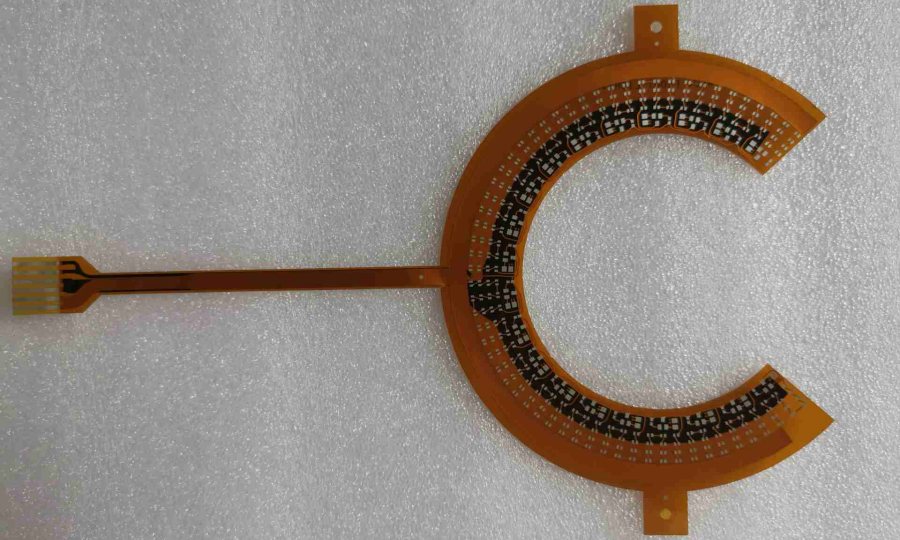

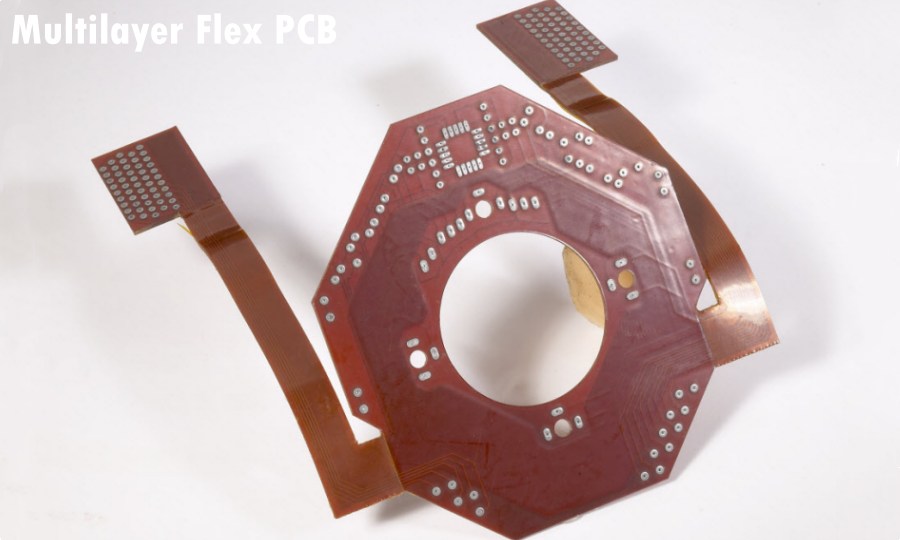

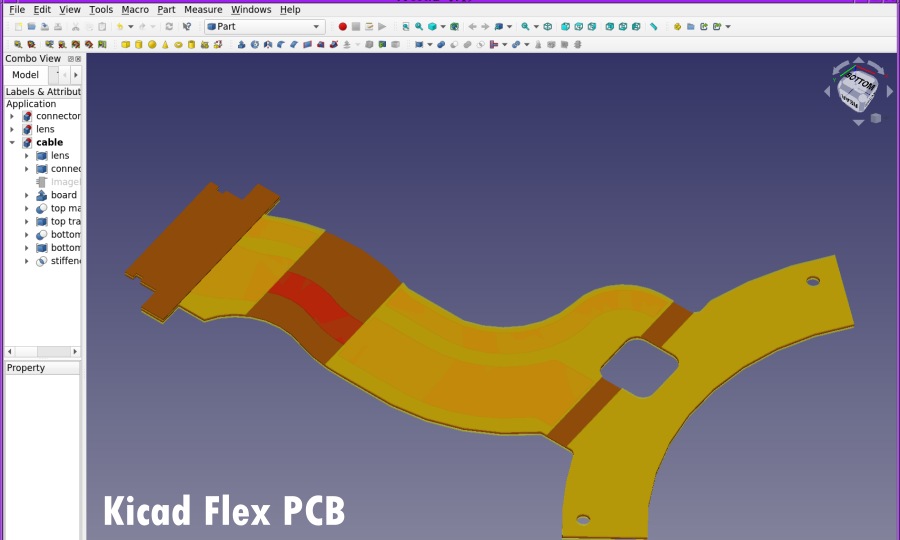

Flexible PCB We Served

Types of Flexible PCBs

Understanding the different types of flexible PCBs is essential for selecting the right solution for your application. Each type offers distinct advantages and is suited for specific use cases.

Single-Layer Flexible PCBs

Single-layer flexible PCBs are the simplest and most cost-effective type, consisting of a single conductor layer laminated to one side of a flexible substrate. These circuits are ideal for simple interconnections and applications where cost is a primary concern. Common applications include LED strip connections, battery packs, and simple sensor interconnects.

The manufacturing process for single-layer flex PCBs is straightforward, involving substrate preparation, copper deposition, etching, and coverlay application. This simplicity translates to lower costs and shorter lead times, making them attractive for high-volume consumer electronics applications.

Double-Layer Flexible PCBs

Double-layer flexible PCBs feature conductor patterns on both sides of the substrate, connected through plated through-holes (PTHs) or vias. This configuration provides higher circuit density and more routing flexibility compared to single-layer designs. The additional layer allows for more complex circuits while maintaining the benefits of flexibility.

These PCBs are commonly used in applications requiring higher component density, such as smartphone flex cables, tablet interconnects, and automotive sensor arrays. The two-layer design enables better signal integrity through proper ground plane implementation and reduces electromagnetic interference (EMI).

Multi-Layer Flexible PCBs

Multi-layer flexible PCBs incorporate three or more conductor layers, offering the highest circuit density and most sophisticated routing capabilities. These advanced circuits can include dedicated power and ground planes, controlled impedance traces, and complex signal routing patterns. Manufacturing multi-layer flex PCBs requires advanced lamination processes and precise layer alignment.

Applications for multi-layer flexible PCBs include high-speed digital circuits, RF/microwave applications, and complex automotive electronic systems. The multiple layers enable better signal integrity, reduced crosstalk, and improved electromagnetic compatibility (EMC).

Rigid-Flex PCBs

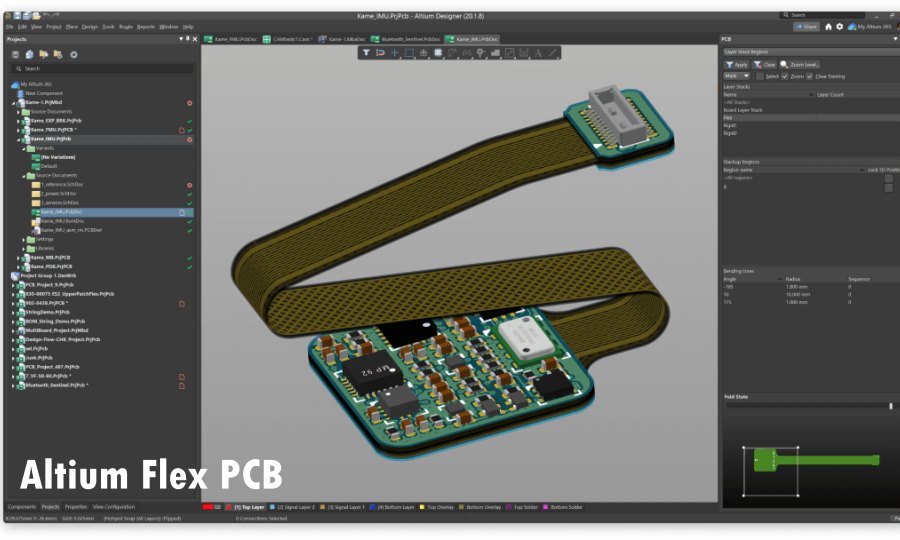

Rigid-flex PCBs combine rigid and flexible sections in a single circuit board assembly, offering the best of both worlds. The rigid sections provide mounting points for components and connectors, while the flexible sections enable movement and three-dimensional routing. This hybrid approach eliminates the need for separate connectors and cables, improving reliability and reducing assembly costs.

These advanced PCBs are extensively used in aerospace, military, medical devices, and high-end consumer electronics where reliability and space efficiency are critical. The rigid-flex design reduces interconnect points, improving overall system reliability and reducing potential failure modes.

Applications of Flexible PCBs in 2025

The versatility of flexible PCBs has led to their adoption across numerous industries and applications. As technology advances, new use cases continue to emerge, driving innovation and market growth.

Consumer Electronics

The consumer electronics industry remains the largest market for flexible PCBs, driven by the constant demand for smaller, lighter, and more feature-rich devices. Smartphones utilize numerous flex circuits for camera modules, display connections, battery packs, and antenna systems. The latest flagship smartphones incorporate over 20 individual flexible PCB assemblies.

Wearable devices represent a rapidly growing segment, with smartwatches, fitness trackers, and health monitoring devices all relying heavily on flexible PCB technology. These applications require circuits that can withstand constant flexing and conform to curved surfaces while maintaining reliable electrical performance.

Tablets, laptops, and convertible devices use flexible PCBs for keyboard connections, display hinges, and internal interconnects. The ability to fold and flex enables new form factors and improves durability compared to traditional cable-based solutions.

Automotive Electronics

The automotive industry has embraced flexible PCBs for numerous applications, driven by the increasing electrification and digitization of vehicles. Advanced driver assistance systems (ADAS) rely on flexible circuits for radar sensors, camera modules, and lidar systems. These applications require circuits that can operate reliably in harsh automotive environments with extreme temperatures, vibrations, and electromagnetic interference.

Electric vehicles (EVs) utilize flexible PCBs in battery management systems, charging interfaces, and power distribution modules. The flexible nature allows these circuits to conform to battery pack geometries and accommodate thermal expansion and contraction cycles.

Infotainment systems, dashboard displays, and advanced lighting systems all incorporate flexible PCBs to enable complex routing in constrained spaces. The automotive industry’s transition toward autonomous vehicles is creating new opportunities for flexible PCB applications in sensor fusion systems and high-speed data processing modules.

Medical Devices

Medical device applications demand the highest levels of reliability and biocompatibility, making flexible PCBs an ideal solution for many applications. Implantable devices such as pacemakers, neural stimulators, and continuous glucose monitors utilize flexible circuits that can conform to body contours and withstand long-term implantation.

Wearable health monitors, including ECG patches, temperature sensors, and pulse oximeters, rely on flexible PCBs to maintain intimate contact with the skin while allowing natural movement. These applications often require specialized biocompatible materials and coatings.

Diagnostic equipment, surgical instruments, and imaging systems incorporate flexible PCBs to enable compact designs and improved functionality. The flexibility allows circuits to be routed through complex mechanical assemblies and tight spaces within medical devices.

Aerospace and Defense

Aerospace and defense applications push the boundaries of flexible PCB technology, requiring circuits that can operate in extreme environments while meeting stringent reliability requirements. Satellite systems utilize flexible PCBs for solar panel connections, antenna feeds, and internal interconnects that must withstand space radiation and temperature cycling.

Military electronics require flexible circuits that can operate in harsh combat environments, including extreme temperatures, vibrations, and electromagnetic interference. Applications include communication systems, radar equipment, and missile guidance systems.

Aircraft electronics systems use flexible PCBs for avionics, engine monitoring, and passenger entertainment systems. The weight savings offered by flexible circuits is particularly valuable in aerospace applications where every gram matters.

Industrial IoT and Automation

The Industrial Internet of Things (IoT) revolution has created new opportunities for flexible PCB applications in sensor networks, automation systems, and monitoring equipment. Flexible circuits enable sensors to be embedded in rotating machinery, curved surfaces, and confined spaces where rigid PCBs would be impractical.

Factory automation systems use flexible PCBs in robotic arms, conveyor systems, and assembly equipment where repeated flexing is required. The durability and reliability of properly designed flexible circuits make them ideal for these demanding applications.

Smart building systems incorporate flexible PCBs in lighting controls, HVAC sensors, and security systems. The ability to route circuits through building structures and around architectural features provides installation flexibility and improved aesthetics.

Benefits and Advantages of Flexible PCBs

Flexible PCBs offer numerous advantages over traditional rigid PCBs and cable-based interconnect solutions, making them the preferred choice for many modern electronics applications.

Space and Weight Reduction

One of the most significant advantages of flexible PCBs is their ability to eliminate bulky connectors and cables, resulting in substantial space and weight savings. In applications where every cubic millimeter matters, such as smartphones and wearable devices, flexible circuits enable more compact designs and lighter products.

The three-dimensional routing capability of flexible PCBs allows designers to utilize space more efficiently by conforming circuits to available packaging constraints. This spatial efficiency often enables the integration of additional features or larger batteries within the same form factor.

Improved Reliability

Flexible PCBs can significantly improve system reliability by eliminating mechanical connectors and solder joints that are common failure points in traditional interconnect solutions. Each eliminated connection point reduces the overall system failure rate and improves long-term reliability.

The monolithic nature of flexible circuits means that all interconnections are formed during the manufacturing process under controlled conditions, rather than being assembled in the field where quality control may be less stringent. This manufacturing approach results in more consistent and reliable interconnections.

Enhanced Design Flexibility

The mechanical flexibility of these circuits enables innovative product designs that would be impossible with rigid PCBs. Designers can create curved interfaces, foldable displays, and complex three-dimensional electronic assemblies that adapt to mechanical constraints rather than dictating them.

This design flexibility extends beyond physical constraints to include electrical performance benefits. Flexible circuits can be designed with controlled impedance characteristics, optimized signal routing, and reduced electromagnetic interference through careful layer stack-up design.

Cost Reduction in Assembly

While flexible PCBs may have higher initial material costs compared to rigid alternatives, they often provide significant cost savings in assembly and manufacturing. The elimination of connectors, cables, and manual assembly steps reduces both material costs and labor requirements.

The ability to integrate multiple functions into a single flexible circuit assembly reduces part count, simplifies inventory management, and decreases the complexity of the assembly process. These benefits become more significant in high-volume production environments.

Dynamic Flexing Capability

Unlike rigid PCBs that can only withstand minimal mechanical stress, flexible circuits are designed to withstand millions of flex cycles without failure. This capability enables applications such as printer heads, hard disk drive actuators, and robotic joints where continuous movement is required.

The dynamic flexing performance of flexible PCBs can be optimized through careful design of conductor geometry, material selection, and layer stack-up configuration. Proper design can achieve flex life exceeding 100 million cycles in demanding applications.

Design Considerations for Flexible PCBs

Designing successful flexible PCB applications requires careful consideration of numerous factors that differ significantly from rigid PCB design practices. Understanding these considerations is crucial for achieving optimal performance and reliability.

Material Selection

The choice of substrate material is fundamental to flexible PCB performance and cost. Polyimide offers the best overall performance with excellent thermal stability, chemical resistance, and mechanical properties, but comes at a premium cost. For cost-sensitive applications, polyester (PET) provides adequate performance for static flexing applications.

Adhesive selection is equally important, as it affects the circuit’s thermal performance, flexibility, and long-term reliability. Adhesiveless constructions, where copper is directly bonded to the substrate without intermediate adhesive layers, offer superior thermal and mechanical performance but require more sophisticated manufacturing processes.

Conductor thickness must be carefully selected based on current carrying requirements and flexibility needs. Thicker copper provides better current carrying capacity and lower resistance but reduces flexibility and increases the minimum bend radius. The trade-off between electrical performance and mechanical flexibility is a key design consideration.

Bend Radius and Flex Life

The minimum bend radius is a critical design parameter that affects both the immediate functionality and long-term reliability of flexible circuits. The bend radius is typically expressed as a multiple of the total circuit thickness, with tighter bends requiring special design considerations.

For single-layer circuits, the minimum bend radius is typically 6-10 times the total thickness for dynamic flexing applications. Multi-layer circuits require larger bend radii due to the increased thickness and potential for delamination between layers. Static flexing applications can accommodate tighter bend radii than dynamic flexing applications.

Flex life requirements must be established early in the design process, as they significantly impact material selection, conductor design, and manufacturing processes. Applications requiring millions of flex cycles need specialized conductor geometries and material systems optimized for dynamic flexing.

Trace Routing and Geometry

Conductor trace routing in flexible circuits requires special attention to stress distribution and flexibility optimization. Traces should be routed perpendicular to the flexing axis to minimize stress concentration and maximize flex life. Curved traces are preferred over sharp corners, which can create stress concentration points.

The conductor pattern geometry significantly affects flexibility and reliability. Hatched or serpentine conductor patterns can improve flexibility but may impact electrical performance. For high-frequency applications, the trade-off between flexibility and signal integrity must be carefully evaluated.

Via placement in flexible circuits requires special consideration, as vias create stress concentration points that can lead to failure during flexing. Vias should be located in rigid sections when possible, or in areas that experience minimal stress during flexing.

Layer Stack-up Design

Multi-layer flexible PCB stack-up design is more complex than rigid PCB design due to the additional considerations of flexibility and stress distribution. The layer arrangement affects both electrical performance and mechanical properties, requiring careful optimization.

Symmetrical layer stack-ups are preferred for multi-layer flexible circuits to minimize warping and stress concentration during flexing. The placement of ground and power planes can significantly impact both electrical performance and flexibility, requiring careful consideration of the application requirements.

The choice between adhesive and adhesiveless constructions affects the layer stack-up options and performance characteristics. Adhesiveless constructions generally provide better performance but may limit material and processing options.

Environmental Considerations

Flexible PCBs may be exposed to a wide range of environmental conditions, including temperature extremes, humidity, chemicals, and mechanical stress. The design must account for these environmental factors to ensure reliable long-term operation.

Temperature cycling can cause differential expansion and contraction between different materials in the flexible circuit, leading to stress and potential failure. The coefficient of thermal expansion (CTE) mismatch between different materials must be considered in the design.

Chemical resistance requirements may dictate material selection and protective coatings. Medical and automotive applications often have specific chemical exposure requirements that must be addressed in the design phase.

Signal Integrity and EMI Considerations

High-speed digital and RF applications require careful attention to signal integrity and electromagnetic interference (EMI) considerations. The flexible nature of these circuits can complicate impedance control and noise suppression compared to rigid PCBs.

Controlled impedance traces can be implemented in flexible circuits, but require careful design of the dielectric stack-up and conductor geometry. The flexibility of the circuit can cause impedance variations during flexing, which may need to be accounted for in high-speed applications.

Ground plane implementation in flexible circuits requires special consideration, as traditional solid ground planes may compromise flexibility. Hatched ground planes or carefully designed ground networks may be necessary to maintain both flexibility and EMI performance.

Manufacturing Process and Quality Control

The manufacturing of flexible PCBs involves specialized processes and equipment that differ significantly from rigid PCB production. Understanding these processes is important for designers to optimize their designs for manufacturability and cost.

Substrate Preparation

The manufacturing process begins with substrate preparation, where the flexible dielectric material is cleaned and prepared for conductor application. Polyimide films are typically supplied in rolls and must be handled carefully to avoid contamination and mechanical damage.

Surface treatment of the substrate is critical for achieving good adhesion between the dielectric and conductor layers. This may involve chemical etching, plasma treatment, or other surface modification techniques depending on the material system used.

For adhesiveless constructions, specialized substrate materials with integrated adhesion promoters are used, eliminating the need for separate adhesive layers and improving overall performance.

Conductor Application

Copper conductors are typically applied through electrodeposition (plating) or sputtering processes. Electrodeposition provides excellent thickness control and uniformity but requires seed layer preparation and specialized plating processes optimized for flexible substrates.

Sputtering can provide very thin, uniform conductor layers and is often used for fine-pitch applications or specialized conductor materials. However, sputtered layers typically require additional processing steps to achieve adequate thickness for most applications.

The conductor application process must be carefully controlled to ensure good adhesion and uniform thickness across the entire circuit area. Process parameters such as temperature, chemistry, and current density must be optimized for flexible substrate materials.

Circuit Patterning

Circuit patterning in flexible PCBs follows similar principles to rigid PCB manufacturing but requires specialized photolithography processes adapted for flexible substrates. The flexible nature of the substrate can complicate pattern registration and dimensional stability during processing.

Etching processes must be carefully controlled to achieve the desired conductor geometry while maintaining the integrity of the flexible substrate. The etching chemistry and parameters may need to be optimized for the specific material system used.

Advanced manufacturing facilities may use laser direct imaging (LDI) or other digital patterning techniques that can provide better registration and dimensional control compared to traditional photolithographic processes.

Lamination and Assembly

Multi-layer flexible PCBs require specialized lamination processes that can maintain layer registration while avoiding damage to the flexible substrate. The lamination pressure, temperature, and cycle time must be carefully controlled to achieve good layer-to-layer adhesion without compromising flexibility.

Through-hole plating in flexible circuits requires special attention to ensure good plating coverage and adhesion at the hole walls. The flexible substrate may deform during plating, requiring specialized fixturing and processing techniques.

Component assembly on flexible circuits often requires specialized techniques and equipment due to the flexible nature of the substrate. Support fixtures may be necessary during soldering to maintain dimensional stability and prevent damage to the circuit.

Quality Control and Testing

Quality control for flexible PCBs requires specialized test methods that account for the unique characteristics of flexible circuits. Electrical testing must be performed both in the flat state and during flexing to ensure reliable performance under operating conditions.

Flex testing is a critical quality control step for dynamic flexing applications. Circuits are subjected to specified numbers of flex cycles while electrical continuity is monitored to verify performance requirements are met.

Visual inspection of flexible circuits requires trained personnel and specialized equipment due to the unique characteristics of flexible substrates and potential defect modes that differ from rigid PCBs.

Cost Factors and Economic Considerations

Understanding the cost drivers for flexible PCB manufacturing is essential for making informed design decisions and optimizing the total cost of ownership for electronic products.

Material Costs

Flexible PCB materials are typically more expensive than rigid PCB materials due to their specialized nature and lower production volumes. Polyimide substrates can cost 3-5 times more than standard FR4 materials, while specialized adhesives and coverlay materials add additional cost.

The cost differential between different flexible substrate materials can be significant, with high-performance polyimide materials commanding premium pricing compared to polyester alternatives. The choice of material system significantly impacts the overall cost of the finished circuit.

Copper foil costs for flexible applications are typically higher than rigid PCB applications due to the specialized adhesion treatments and thinner foil options required for flexibility. The conductor thickness selection affects both performance and cost, requiring careful optimization.

Manufacturing Complexity

The manufacturing complexity of flexible PCBs is generally higher than rigid PCBs, requiring specialized equipment, processes, and expertise. This complexity translates to higher manufacturing costs, particularly for complex multi-layer designs.

Layer count significantly affects manufacturing cost, with multi-layer flexible circuits requiring proportionally higher costs due to the additional processing steps and increased complexity. The cost increase is not linear, with each additional layer adding more complexity than the previous one.

Tighter tolerances and feature sizes increase manufacturing costs due to the need for more sophisticated equipment and processes. High-density interconnect (HDI) features such as microvias add significant cost and complexity to flexible PCB manufacturing.

Volume Considerations

Production volume has a significant impact on flexible PCB costs due to the specialized tooling and setup requirements. Low-volume prototyping can be extremely expensive on a per-unit basis, while high-volume production can achieve more reasonable cost levels.

The break-even point for flexible PCBs versus alternative interconnect solutions is typically higher than for rigid PCBs due to the higher initial tooling and setup costs. However, the elimination of connectors and assembly steps can provide cost savings that offset the higher material costs in high-volume applications.

Design optimization for high-volume production can significantly reduce costs through panelization, standard material utilization, and process optimization. Early engagement with manufacturing partners is essential for achieving optimal cost and performance.

Total Cost of Ownership

When evaluating flexible PCB costs, it’s important to consider the total cost of ownership rather than just the initial material cost. The elimination of connectors, cables, and assembly steps can provide significant cost savings that offset higher material costs.

Improved reliability and reduced field failures can provide substantial cost savings in warranty costs and customer satisfaction. The quantification of these benefits requires careful analysis of the specific application and operating environment.

Design optimization for manufacturing can significantly impact the total cost of ownership through reduced assembly time, improved yield, and simplified inventory management. These benefits become more significant in high-volume production environments.

Future Trends and Innovations in 2025

The flexible PCB industry continues to evolve rapidly, driven by emerging applications, advanced materials, and innovative manufacturing processes. Understanding these trends is essential for staying competitive in the evolving electronics market.

Advanced Materials Development

New substrate materials are being developed to address the limitations of current polyimide and polyester materials. Liquid crystal polymer (LCP) substrates offer superior electrical properties for high-frequency applications but come with higher costs and processing complexity.

Thermoplastic substrates are being developed to enable recyclable flexible circuits and simplified manufacturing processes. These materials may offer cost advantages and environmental benefits compared to traditional thermoset materials.

Advanced conductor materials including silver nanowires, carbon nanotubes, and conductive polymers are being investigated for specialized applications requiring unique properties such as stretchability or transparency.

Manufacturing Process Innovations

Additive manufacturing techniques including printed electronics and 3D printing are beginning to impact flexible PCB manufacturing. These techniques may enable rapid prototyping and customized production for specialized applications.

Roll-to-roll manufacturing processes are being developed to enable high-volume production of simple flexible circuits at dramatically reduced costs. These processes may enable new applications in disposable electronics and IoT devices.

Laser processing techniques are enabling finer feature sizes and more precise manufacturing control, opening new possibilities for high-density flexible circuits and advanced applications.

Emerging Applications

Foldable and rollable displays represent a major growth opportunity for flexible PCB technology, requiring circuits that can withstand extreme bending and repeated folding cycles. These applications are driving innovations in materials and design techniques.

Stretchable electronics represent the next frontier for flexible circuit technology, enabling applications in wearable devices, medical implants, and soft robotics. This technology requires new materials and design approaches that go beyond traditional flexibility requirements.

5G and millimeter-wave applications are creating new opportunities for flexible PCBs in antenna systems and high-frequency interconnects. These applications require specialized materials and design techniques optimized for high-frequency performance.

Environmental and Sustainability Considerations

Environmental regulations and sustainability concerns are driving the development of more environmentally friendly flexible PCB materials and processes. This includes lead-free soldering, halogen-free materials, and recyclable substrates.

Life cycle assessment (LCA) considerations are becoming more important in material and process selection, driving innovations in sustainable manufacturing and end-of-life management for flexible circuits.

The circular economy concept is beginning to influence flexible PCB design and manufacturing, with increased focus on repairability, upgradability, and material recovery at end-of-life.

Conclusion

Flexible PCB technology has become an indispensable enabler of modern electronics innovation, providing the mechanical flexibility and electrical performance needed for today’s demanding applications. As we progress through 2025, the technology continues to evolve, driven by emerging applications in wearable devices, automotive electronics, medical devices, and industrial IoT systems.

The success of flexible PCB implementations depends on careful consideration of design requirements, material selection, manufacturing processes, and cost optimization. Understanding the unique characteristics and requirements of flexible circuits is essential for engineers and designers looking to leverage this technology effectively.

The future of flexible PCB technology is bright, with ongoing innovations in materials, manufacturing processes, and applications opening new possibilities for electronic product design. From foldable displays to stretchable electronics, flexible PCBs will continue to enable breakthrough products that were once considered impossible.

As the electronics industry continues to demand smaller, lighter, and more reliable products, flexible PCB technology will play an increasingly important role in meeting these challenges. The key to success lies in understanding the technology’s capabilities and limitations while leveraging its unique advantages to create innovative solutions that provide real value to end users.

The investment in understanding and implementing flexible PCB technology today will position companies and engineers for success in the rapidly evolving electronics landscape of tomorrow. Whether designing consumer electronics, automotive systems, medical devices, or industrial equipment, flexible PCBs offer compelling solutions that can differentiate products and enable new levels of performance and functionality.